CIMEN

Cement with Negative Carbon IMpact

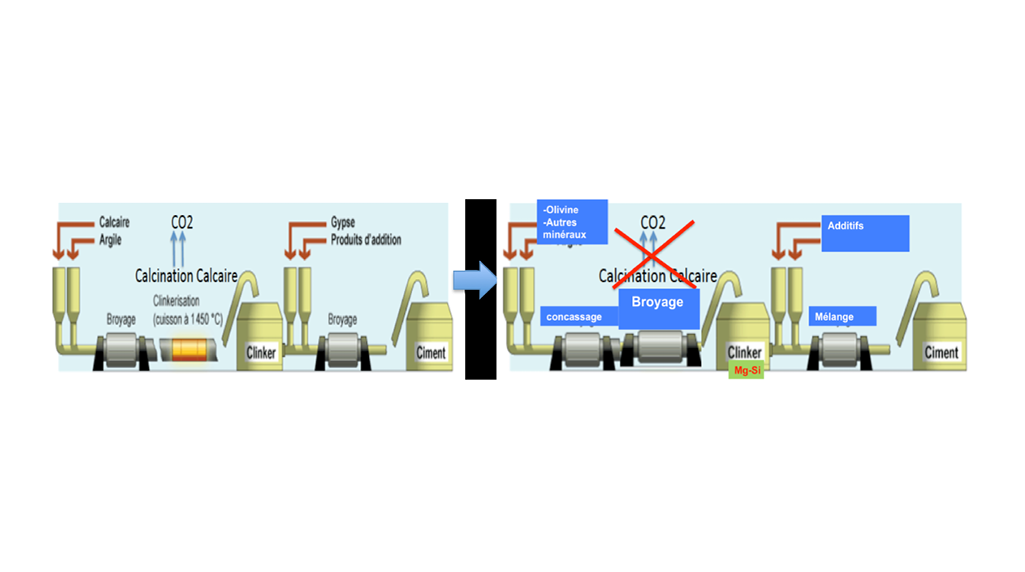

The majority of CO₂ emissions associated with the production of Portland clinker come from the calcination of limestone, a process required to extract calcium, a key element in forming the main hydrated binder phases. Unfortunately, most of the calcium present in nature is incorporated into the limestone. This project aims to explore magnesium-based hydraulic binders (instead of calcium), as this element is abundant in silico-magnesian ultramafic rocks that are not carbonated and are widely available throughout the world. This eliminates the CO₂ emissions intrinsic to the manufacturing process. Silico-magnesian cements have been known for more than 150 years, and they perform as well as Portland cement. However, their large-scale development has been held back for economic reasons, in particular the limited availability of reactive magnesium. We have developed an innovative process to produce silico-magnesian cements with no CO₂ emissions intrinsic to the chemistry from ultramafic rocks (CNRS patent registered). If decarbonated energy is used in the manufacturing process, the overall carbon footprint of this binder could even be negative. In fact, the magnesium hydroxide formed during hydration could sequester atmospheric CO₂ throughout the life of the cementitious product via carbonation. The aim of the overall project is to optimise the manufacturing process and performance of this hydraulic binder and to develop various applications based on it. This involves moving from the laboratory scale (a few dozen grams per batch) to a scale of a few kilograms, then to the tonne scale (industrial scale).