POLAR

Innovative extrusion routes for processing of solid-state batteries

All-solid-state batteries are being promoted as the solution of the future in order to meet the increasing demand for high-capacity storage systems. A major research effort remains to be made on both advanced solid electrolytes, with high ionic conductivities and wide electrochemical stability, and their scalable processing techniques. The teams involved in the present project conduct high-quality research on synthesis of hybrid electrolytes and on innovative extrusion techniques to manufacture components for batteries.

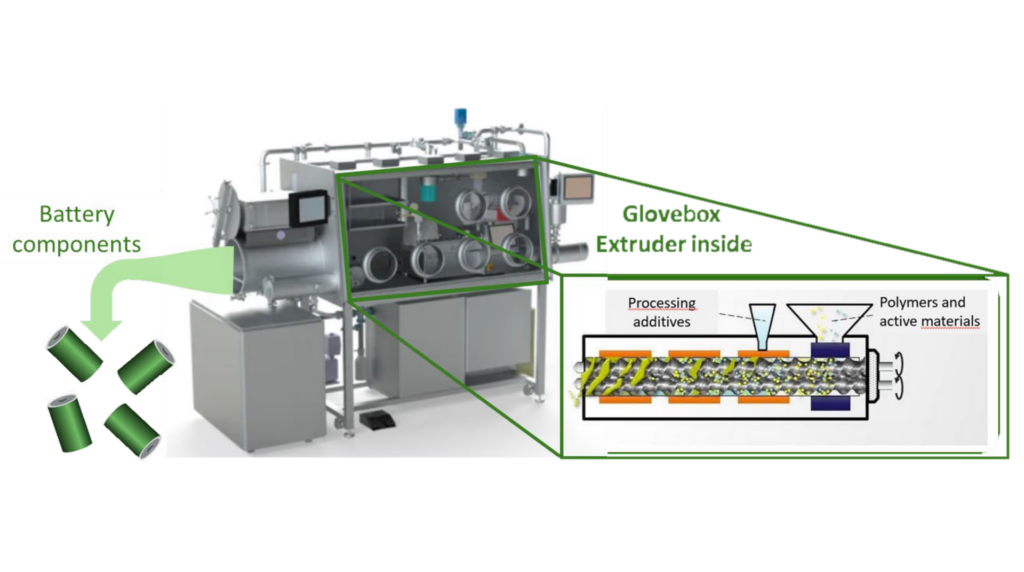

The purpose of this project is to acquire a processing platform with controlled environment for battery electrolyte or electrode extrusion. The platform is composed of two glove boxes, one equipped with an extruder, the second being able to accommodate characterisation equipment such as a rheometer or an Atomic Force Microspcope. This smart labscale setup will allow producing, characterizing and manufacturing highly sensitive and reactive materials under a controlled and inert atmosphere. Around this processing platform, a scientific consortium will be brought together to develop continuous, scalable, efficient processing techniques for all-solid-state batteries, which will pave the way to their large-scale production.