Recycling 2.0

Solid-state recycling of aluminum alloys, an innovative process for enhanced sustainability

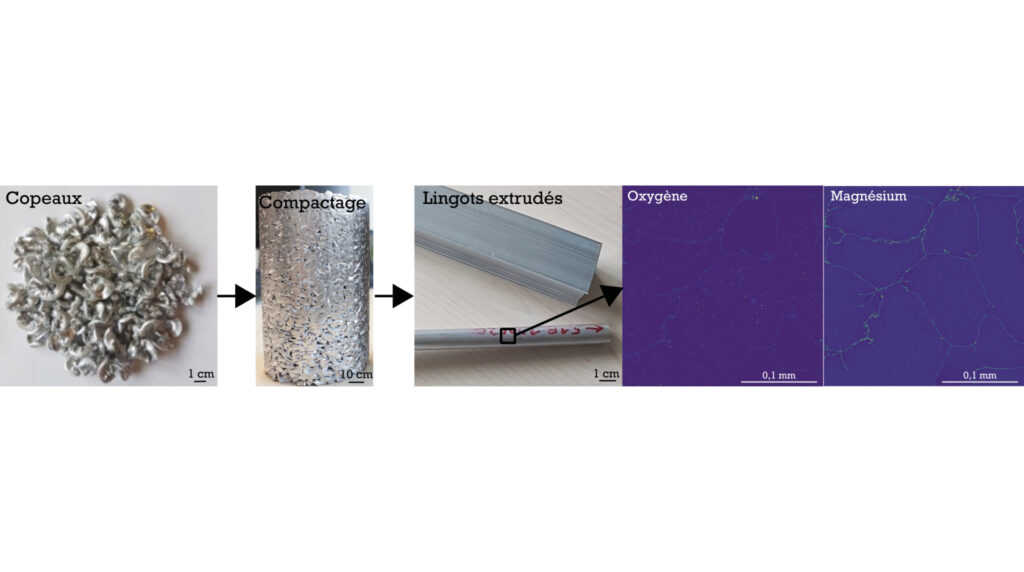

To limit global warming, the European Union has committed to reduce its greenhouse gas (GHG) emissions by at least 40 % in 2030. To meet this ambitious goal, as any other sector, the one of metallic alloy production has to dramatically decrease its emissions. To do so, the development of new recycling methods is a promising approach. Currently, metallic alloys are recycled by re-melting, which already decreases very significantly the GHG emissions compared to the production from ores. To decrease them even more, the solid-state recycling relies on the direct extrusion of the alloys to be recycled.

Solid-state recycling has already been applied to an aluminum alloy and very promising mechanical properties were measured. However, a tendency to decohesion, induced by magnesium oxides, was also observed. Thus, there is an interaction between impurities coming from the process (as oxygen) and alloying elements (as magnesium), which modifies the microstructure and may degrade the mechanical properties. The study, carried on between the IRCP and ICMPE labs, in collaboration with the TU Dortmund, will investigate in greater details the nature and structure of the chips boundaries formed under various processing conditions, mostly using electron microscopy techniques, and the results, coupled with modelling results of the oxidation, should provide guidelines for the selection of experimental processing parameters.