Recycling, Urban Mines and Eco-design

Raw materials and recycling are key issues in the ecological transition. The development of the circular economy to counter the excessive use of materials at all levels is essential.

The objective of the DIM is to contribute to the emergence of technologies necessary for life cycles of materials that respect the environment and health. This includes strategies to find alternative raw materials and achieving significant gains in recycling critical resources. It is also a matter of thinking about reducing the environmental footprint of manufacturing processes (solvents, acids, energy), with equal performance, in order to meet societal demands. Finally, this line of work encompasses the work needed to meet, from the design stage, to the pressure exerted on the environment by the poor management of end-of-life materials. The aim here is to propose strong research actions in favour of a global development of the circular economy, with a view to optimised management of the territories’ resources, reducing their environmental impact and fostering the emergence of virtuous economic and social models.

These are therefore three sub-themes that structure this axis:

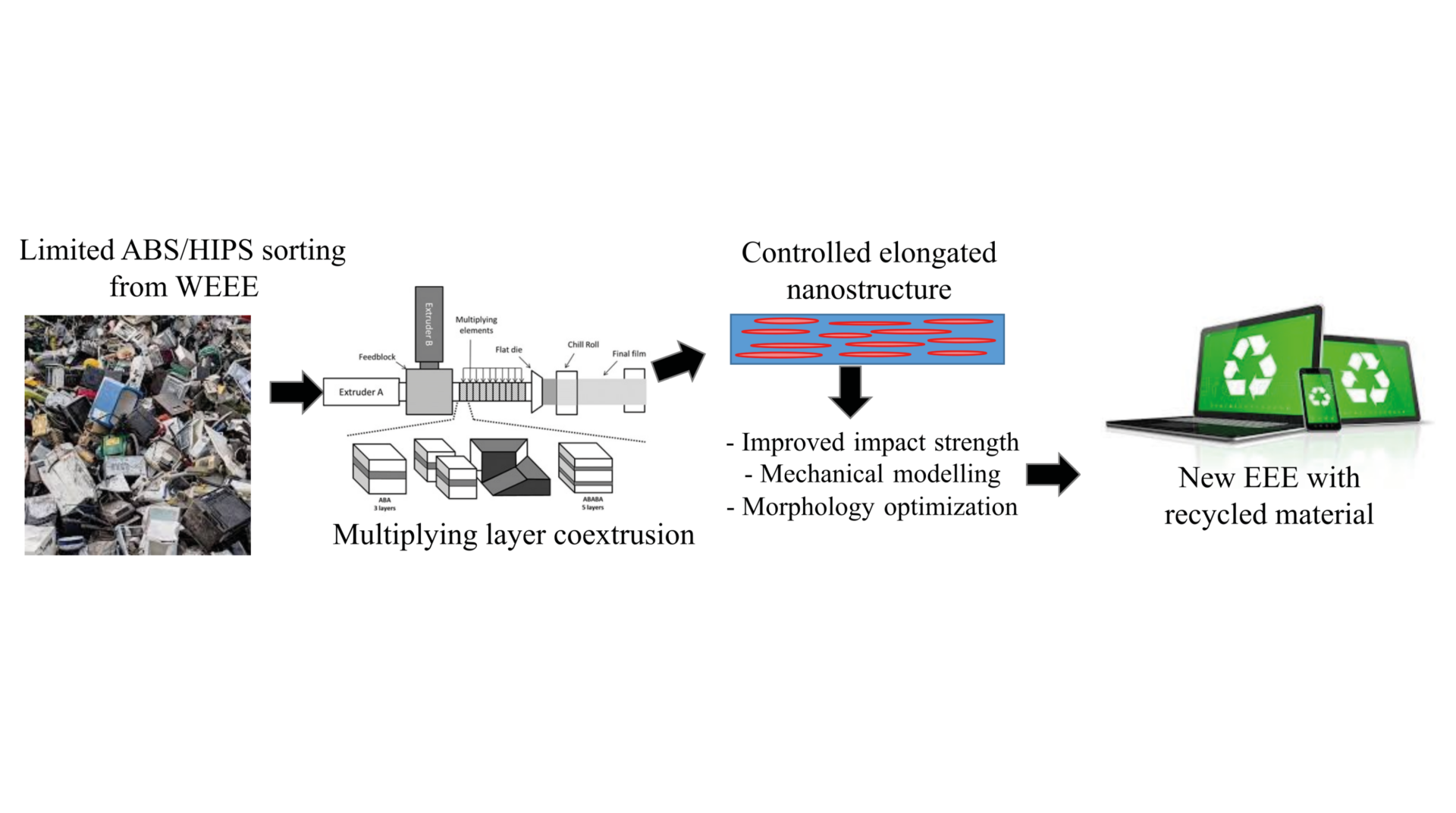

- Techniques for recycling waste electrical and electronic equipment (WEEE). WEEE are often made up partly of rare materials and the two current recycling methods are not eco-compatible: pyrometallurgy is very energy-intensive and releases huge quantities of toxic gases, and hydrometallurgy requires large quantities of corrosive and toxic effluents which must then be treated and purified. Thus, reducing the toxicity of effluents and developing more water-efficient processes are avenues of interest.

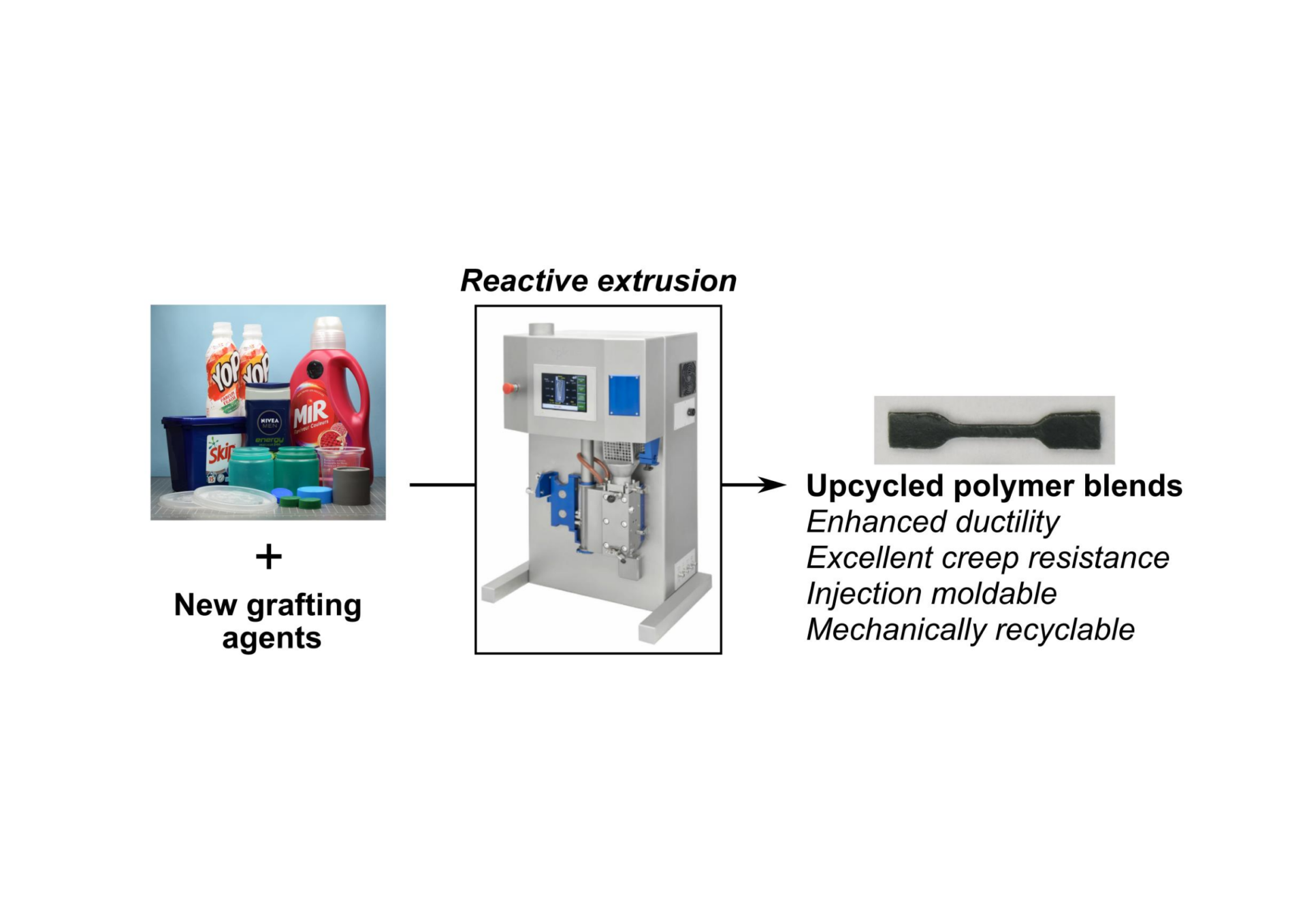

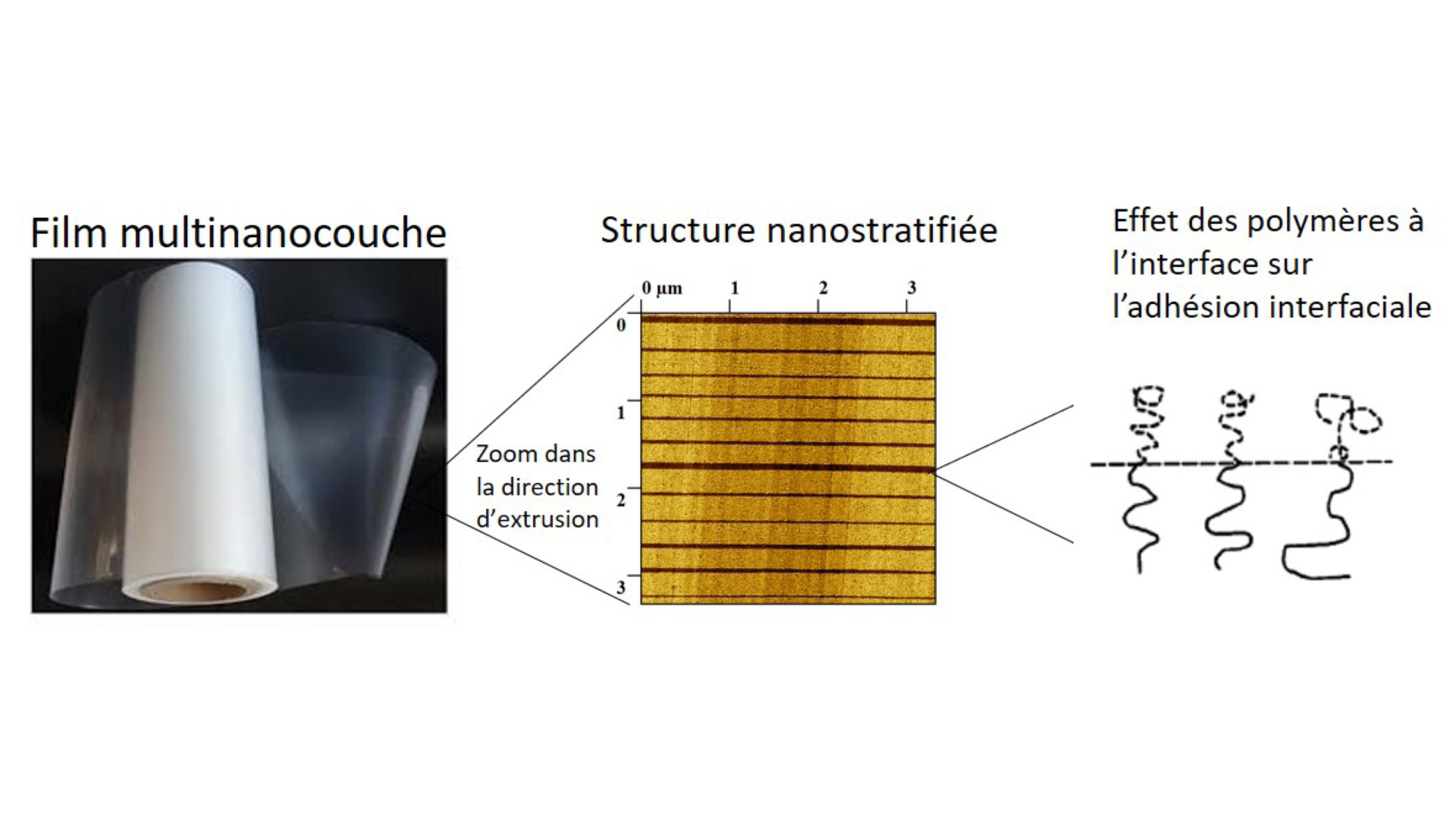

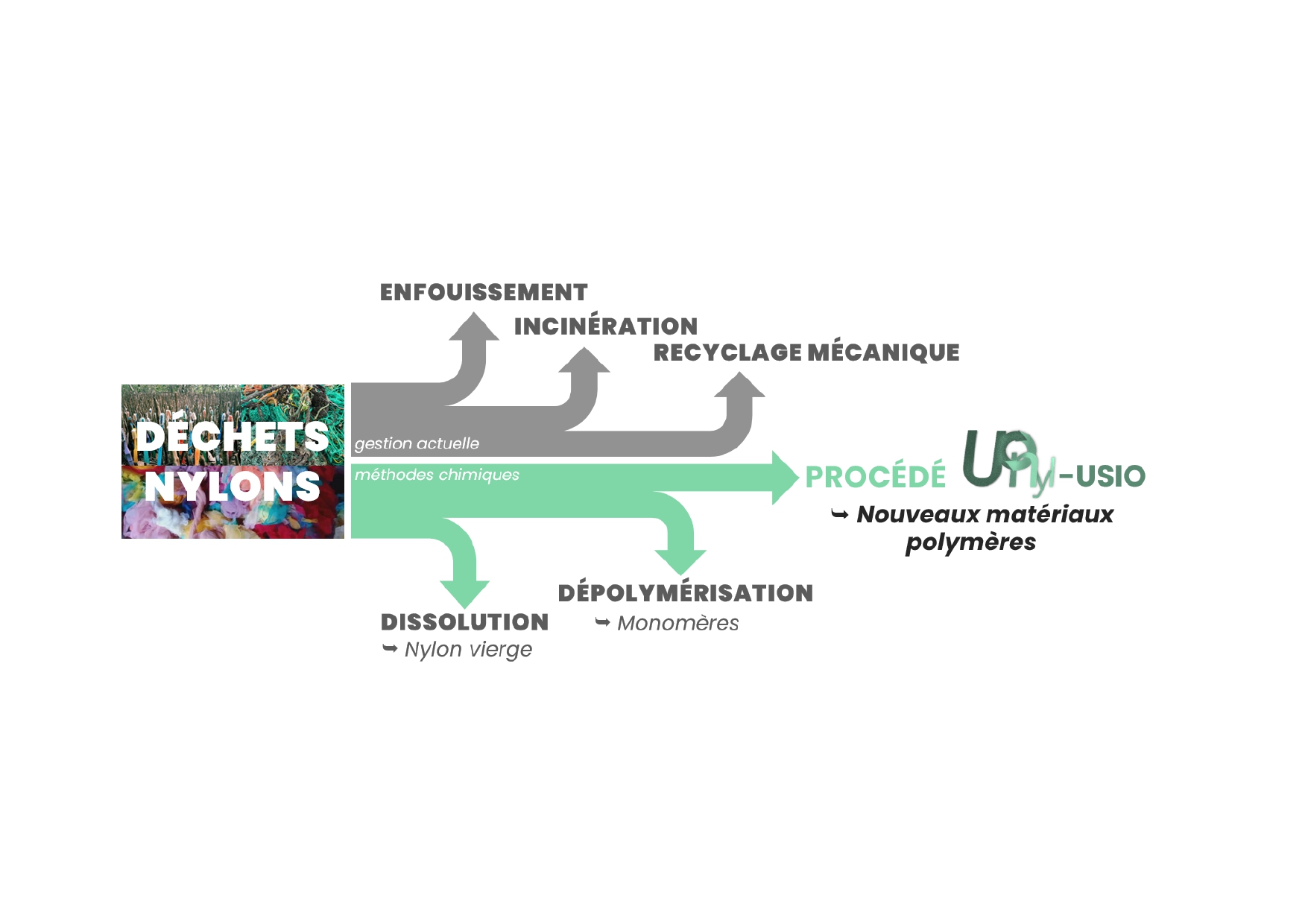

- Recycling and energy recovery, particularly in the case of incineration of household waste. For example, it is a question of developing processes for extracting machefers, which are very rich in metal oxides and sources of reusable raw materials (iron, copper, zinc, aluminium, etc.). It may also be possible to optimize the mechanical recycling of thermoplastic and thermosetting polymers through original recovery strategies by mixing with other polymers before processing. This recycling method, which consists in crushing the polymer and then reshaping it, generally causes a degradation of its mechanical performance.

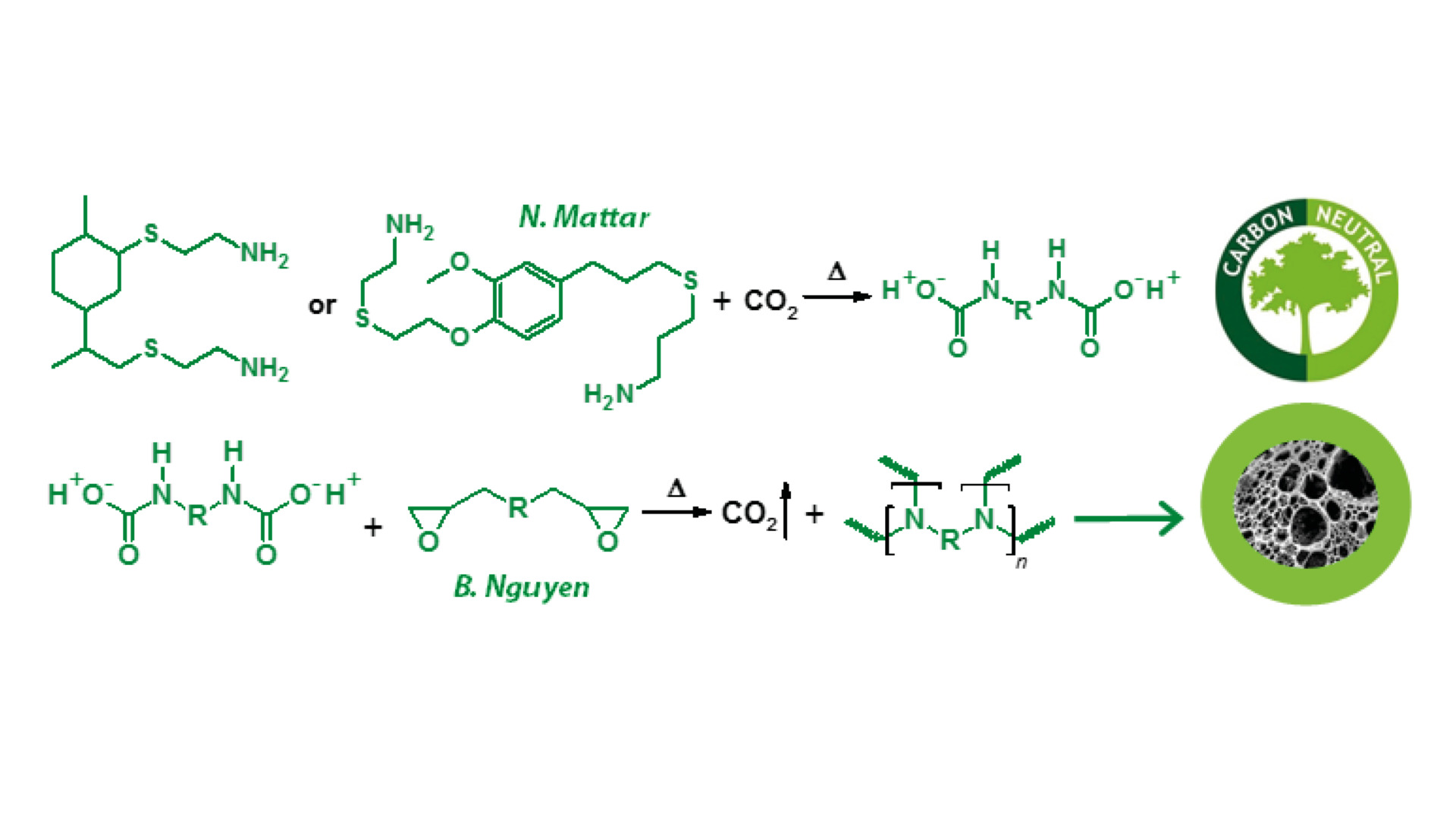

• Eco-design, including value for money, biomass exploitation, biofuel production or polymer development.

Axis managers

Articles et publications

Workshop “What guidance tools are needed for a more sustainable materials research?”

Registration is open until 25 June! The aim of this workshop is to bring together in a single discussion all the R&D players who have or need [...]

Paris region PhD 2025

The Region supports scientific employment linked to the needs of businesses by co-funding PhD grants involving an academic laboratory and a socio-economic partner. For what type of [...]

Relive the TGF ‘Do we still have to invent materials? – Trailer

PG ISAI PSL 2025 Scientific Workshop: Recycling

The Engineering, Applied Sciences and Innovation Graduate Programme (ISAI) of PSL University is organising its Scientific Workshop on 30 January 2025 in the Friedel amphitheatre at Chimie [...]

Allowances 2025

IMPORTANT: the link to submit your projects is: https://materre-2025-1.sciencescall.org Please note: If your project involves a structure from the socio-economic world and includes a digital dimension on [...]

Annual GFP Day – IDF

DIM maTerRE supports the 52nd National Colloquium of the Groupe Français des Polymères, to be held from November 19 to 22, 2024 on Sorbonne University’s Cordeliers campus. [...]

Science Festival 2024: Come Join Us!

DIM MaTerRE will be present at the Science Festival 2024, taking place from October 4 to 13 with a booth at Versailles Saint Quentin University on October [...]

Post-doctoral position

Court for future generations: do we still need to invent new materials?

The MaTerRE DIM is supporting the “ Should new materials still be invented?” tribunal for future generations, an event organized by Lola Lilensten and Mathilde Laurent-Brocq and [...]

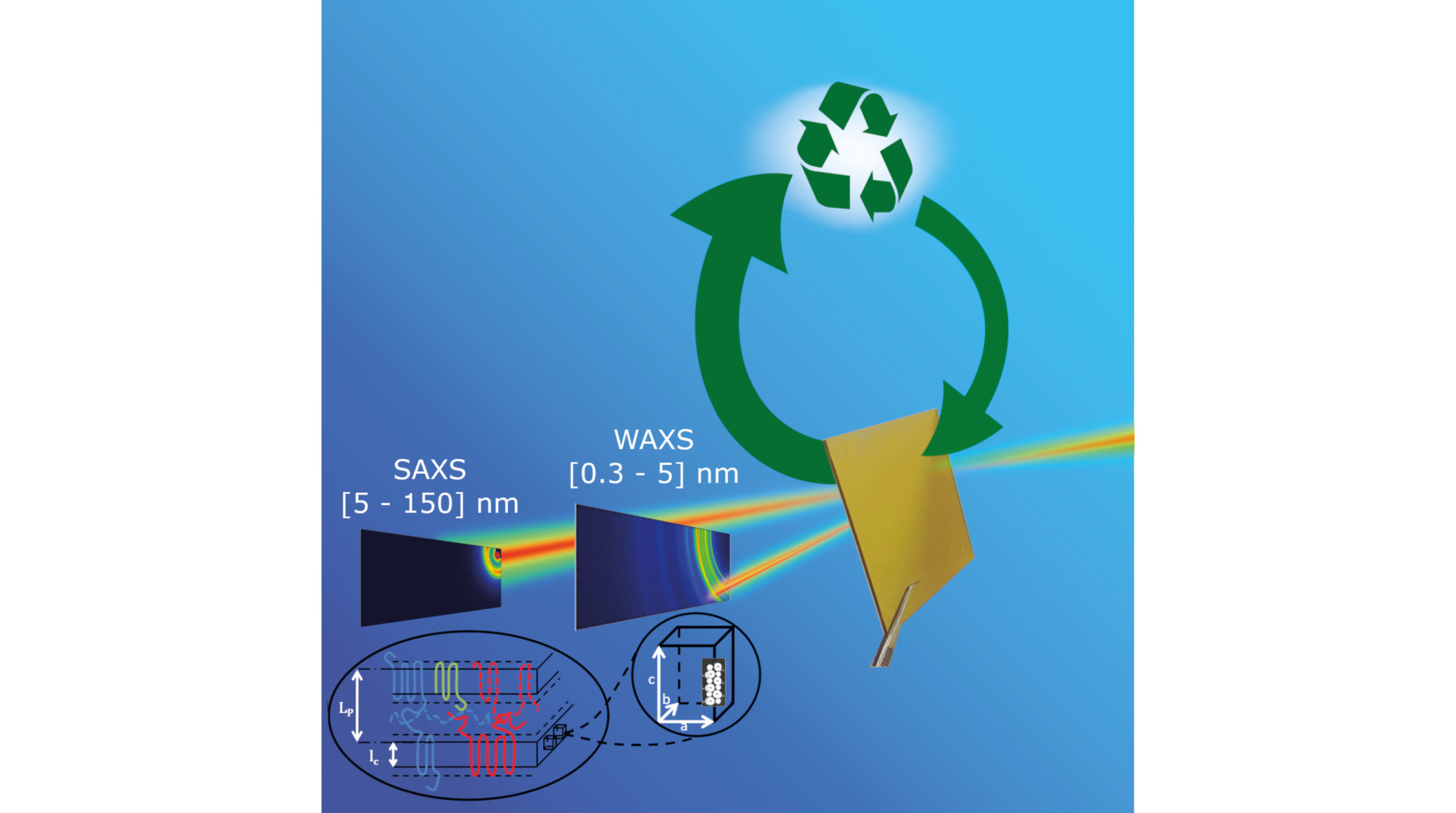

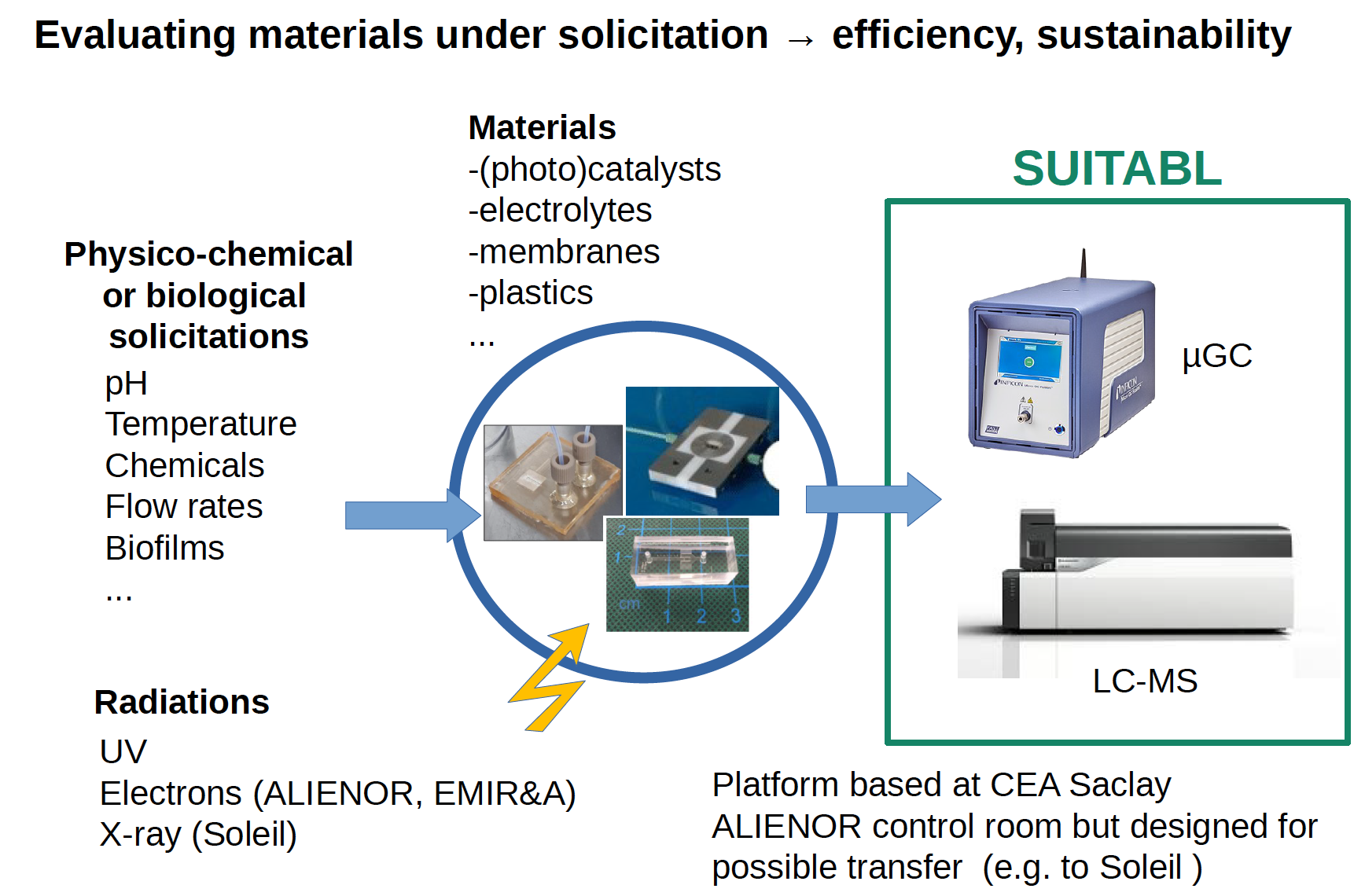

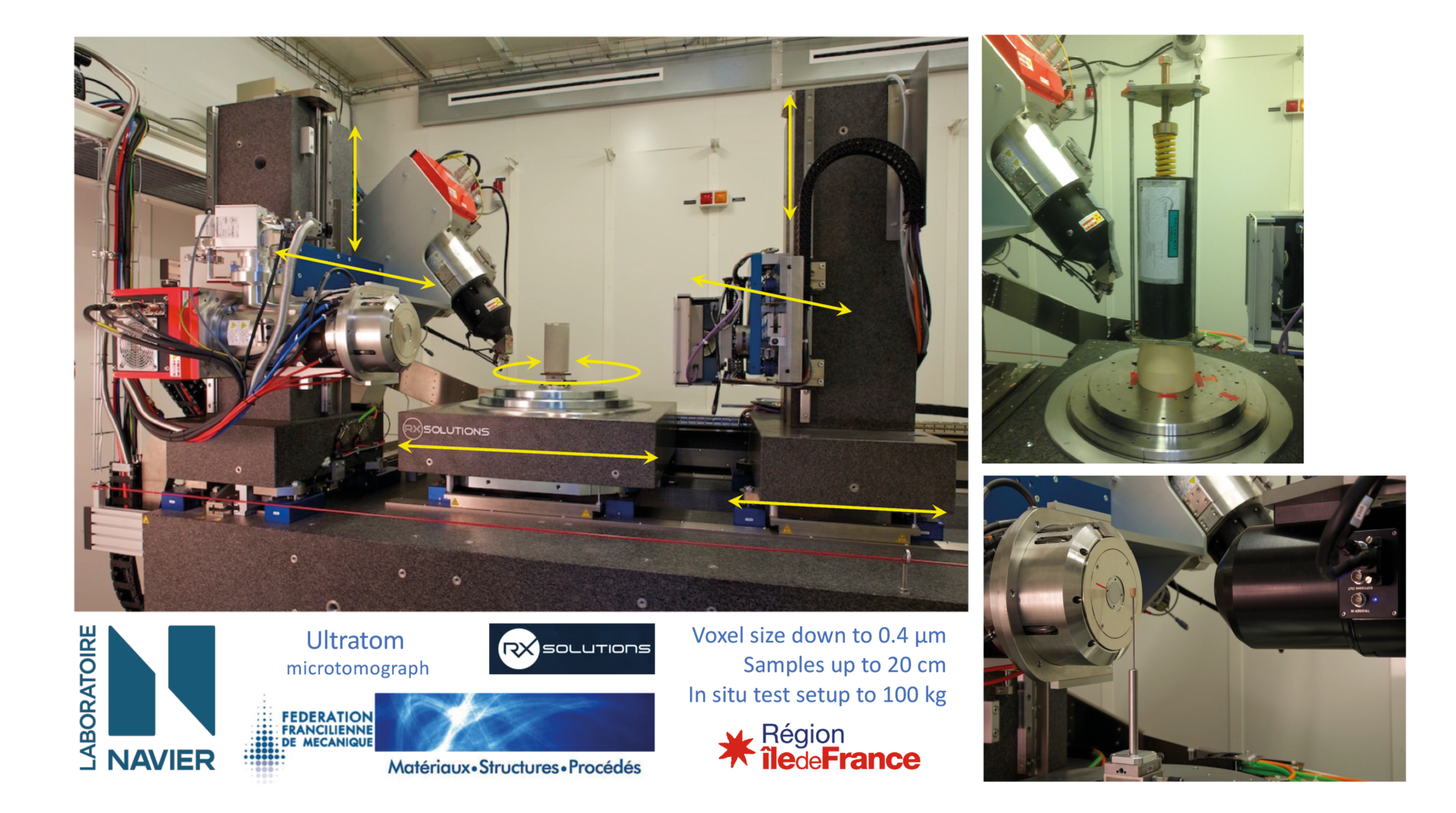

Research Platforms – SESAME FEDER

The Île de France Region launches the call for proposals “Research Platforms – SESAME FEDER”! This call aims to support, develop and create structuring equipment, such as [...]

Postdoctorate – ICMPE

Paris Region PhD

The PrPhD 2024 call for projects is open until 12 March 2024! An informational webinar is organised on 13 february. ELIGIBILITY Launched by the Île-De-France Region, the [...]

Research Engineer – IFPEN

Postdoctoral offer – SIMM – BioCoCo project

Post-doctoral offer – ICMPE

Technology Transfer

Submit your technology transfert project all year round! The call for proposals Technology Transfer on the run of the DIM MaTerRE is intended for any project with [...]

Projets

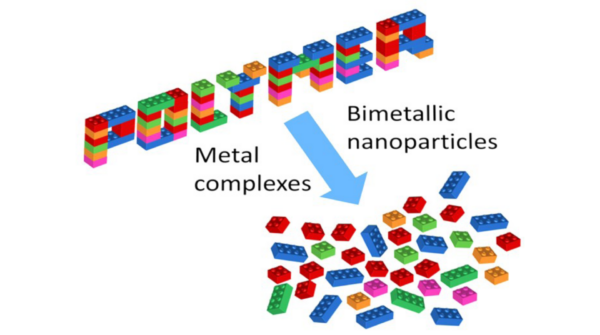

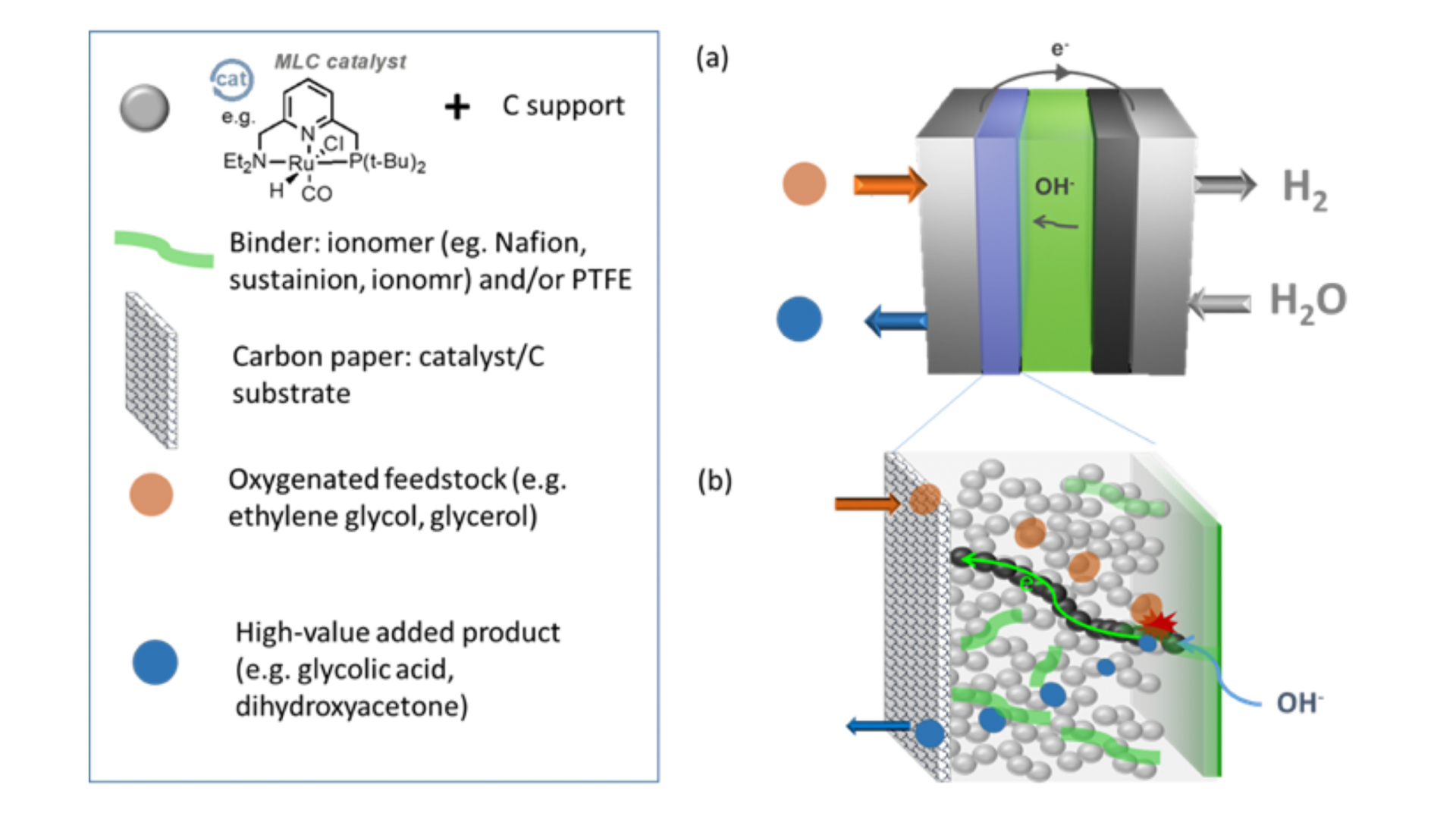

CATHY

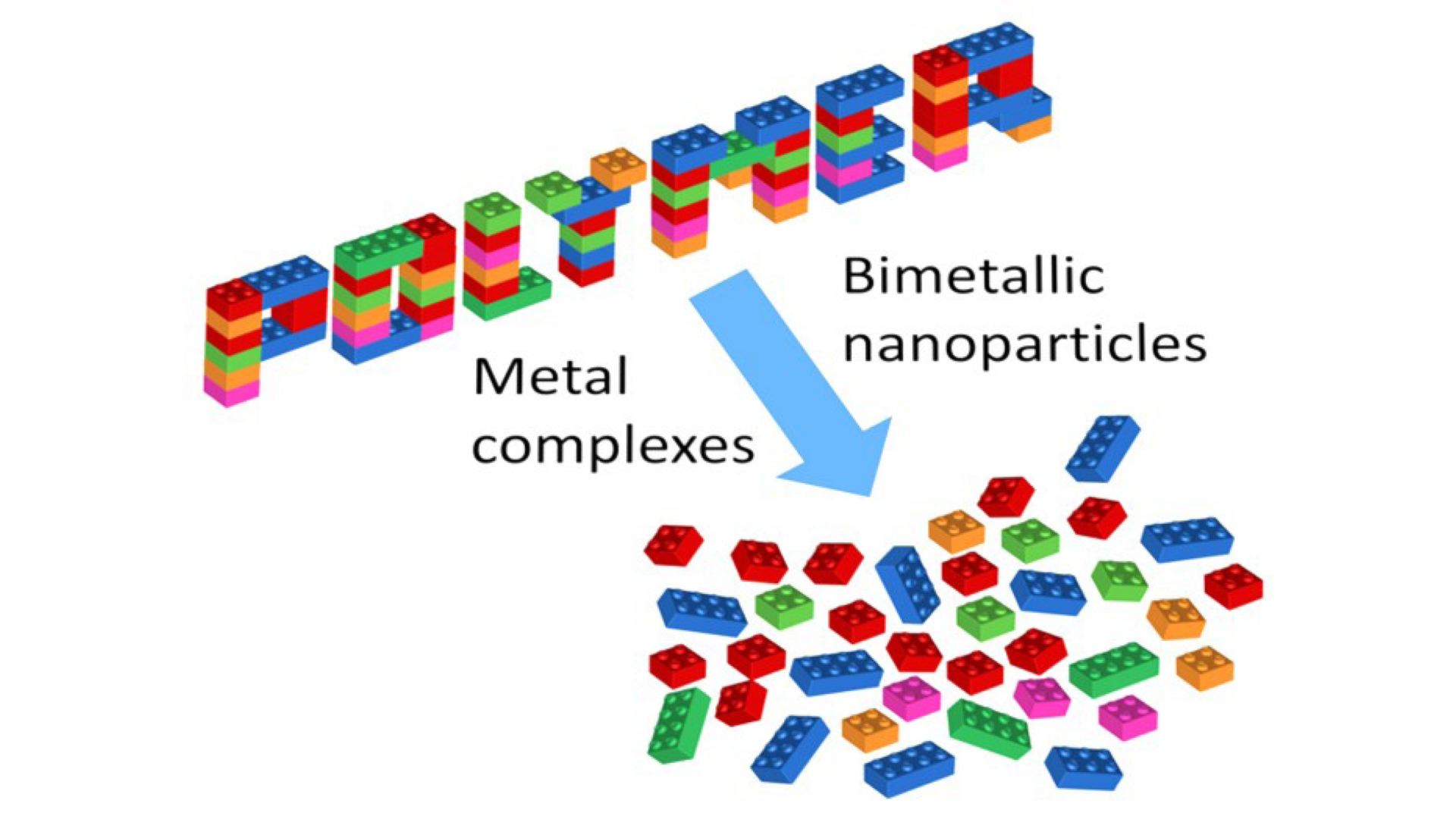

metal CATalysts for HYdrogenative depolymerisation: comparison of molecular complexes and nanoparticles

ECOPOLYM

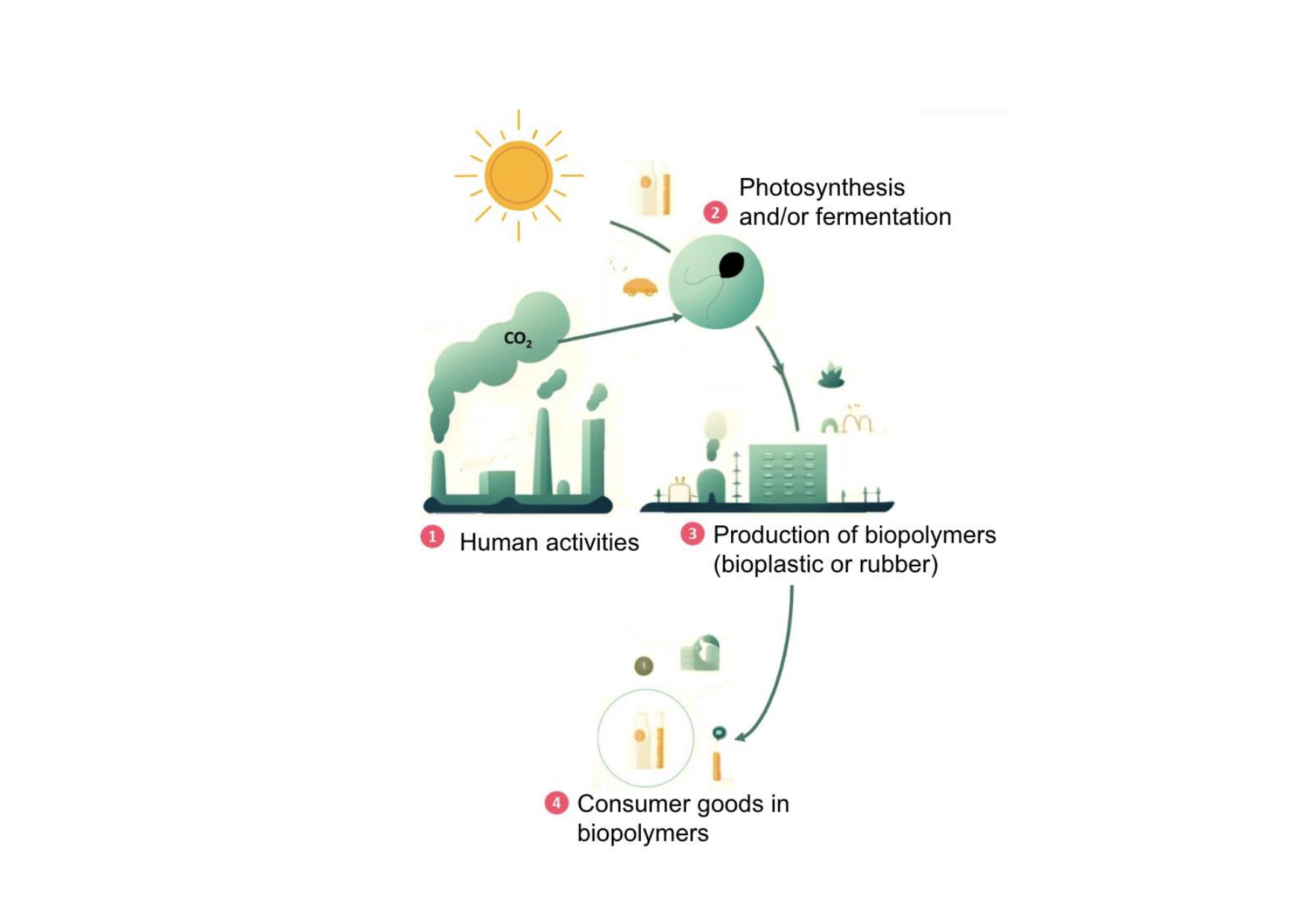

new sustainable source of rubbers and plastics from bacterial fermentation or microalgae-based photosynthetic bioproduction.

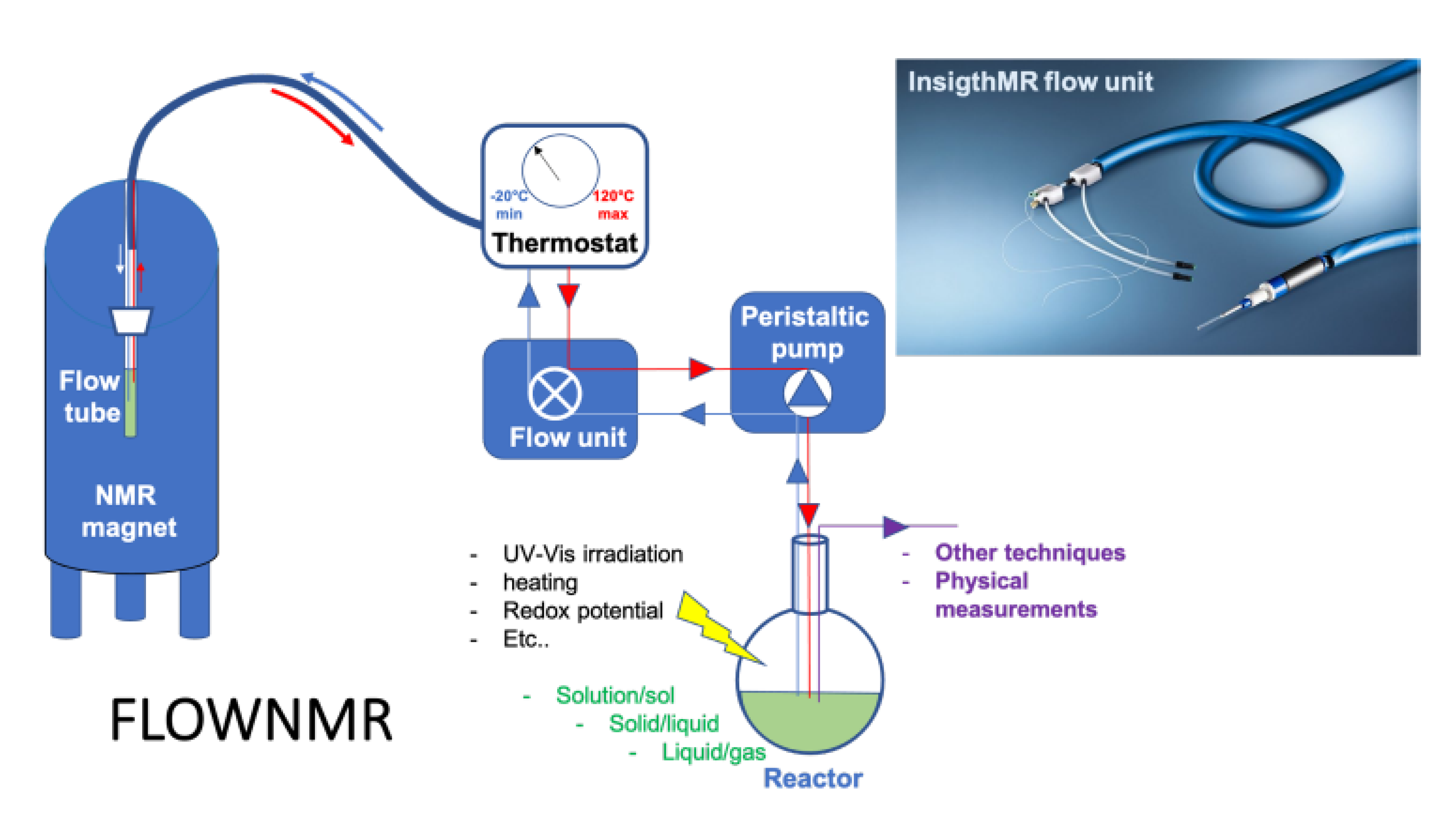

FlowNMR

Flow NMR as a new in situ tool for studying interface processes in solution involving inorganic or hybrid materials

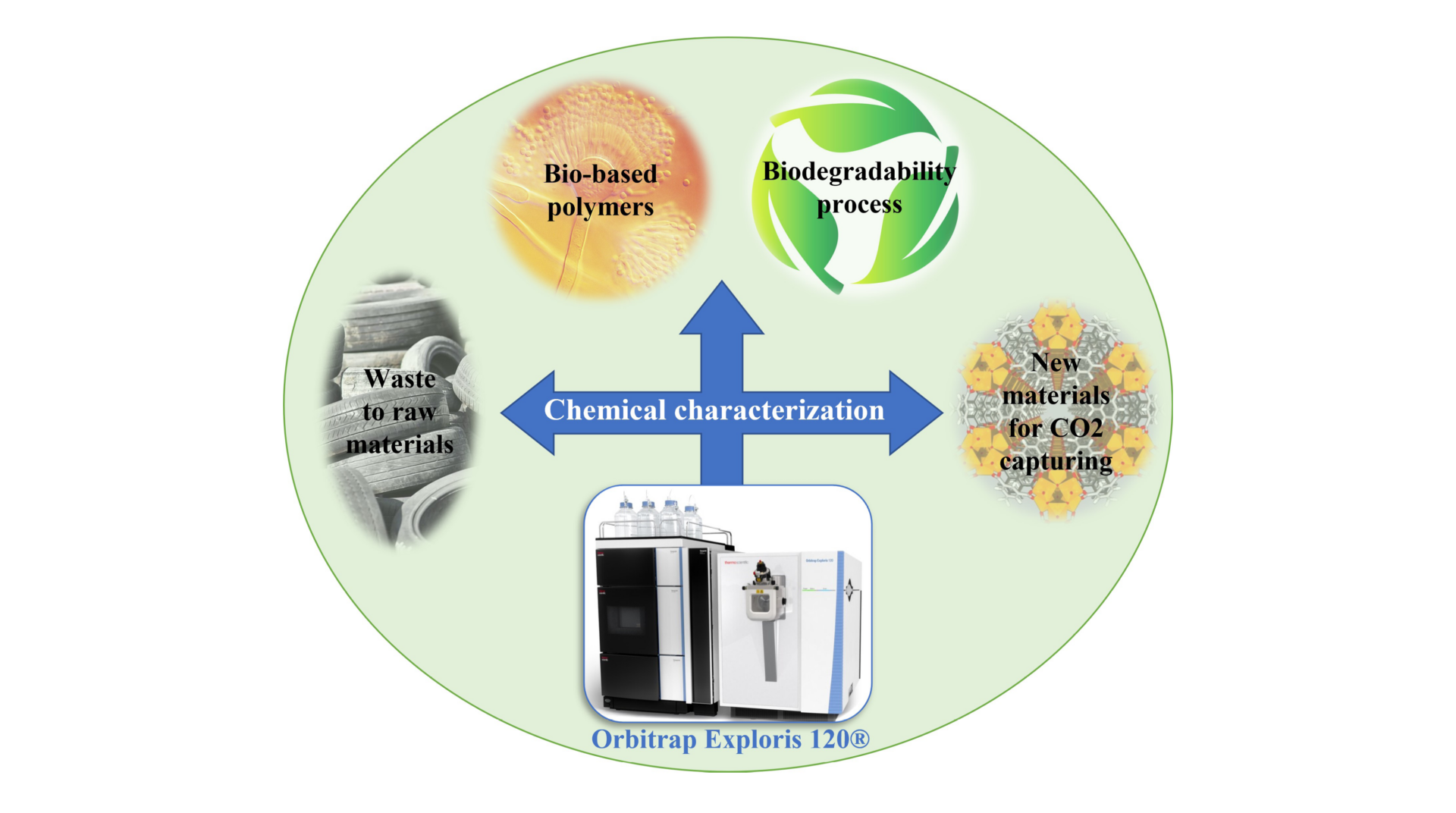

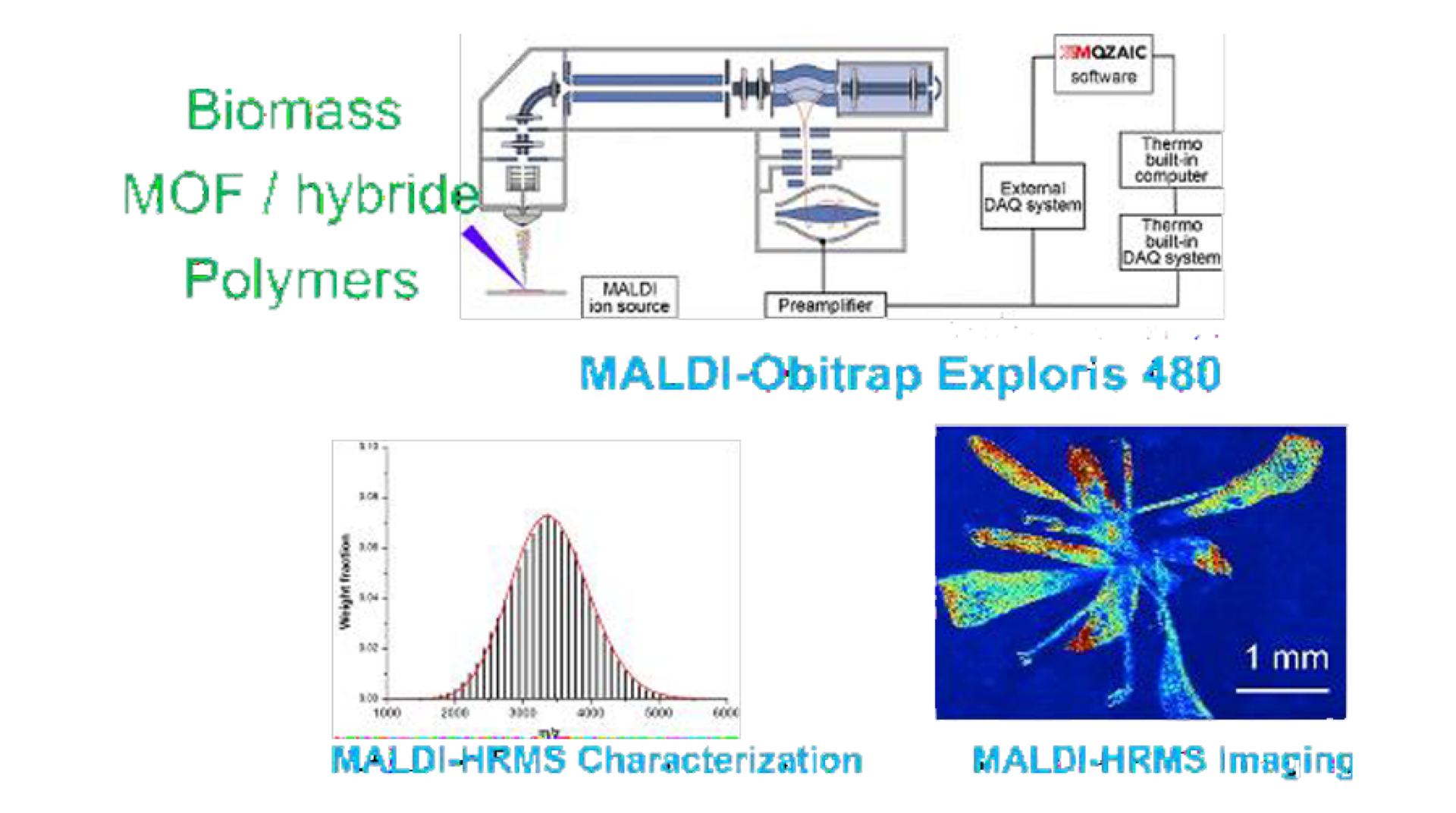

HRMS4MAT

Combining chromatographic and high-resolution mass spectrometry methods to characterize new materials and resources or recover waste materials

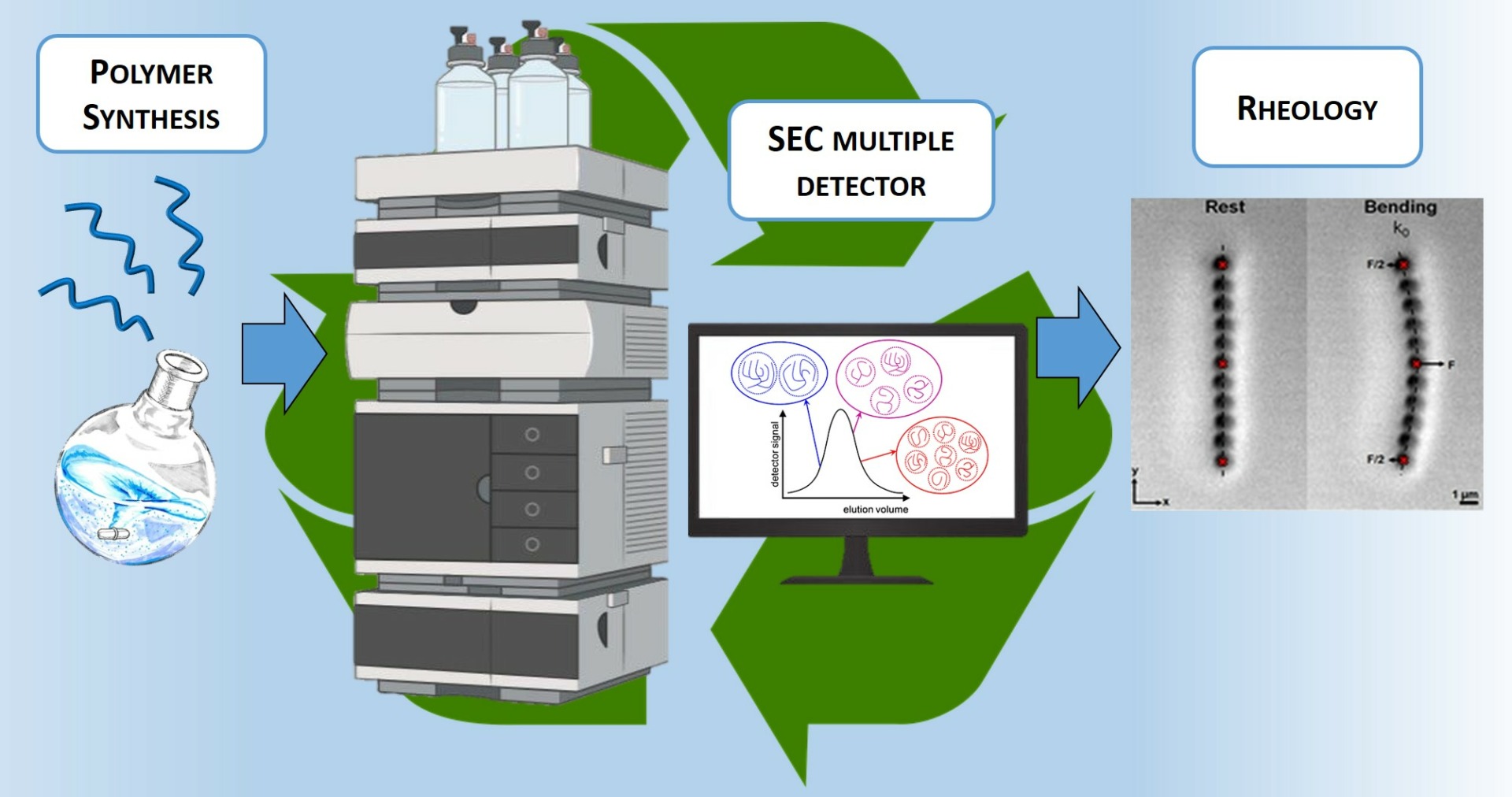

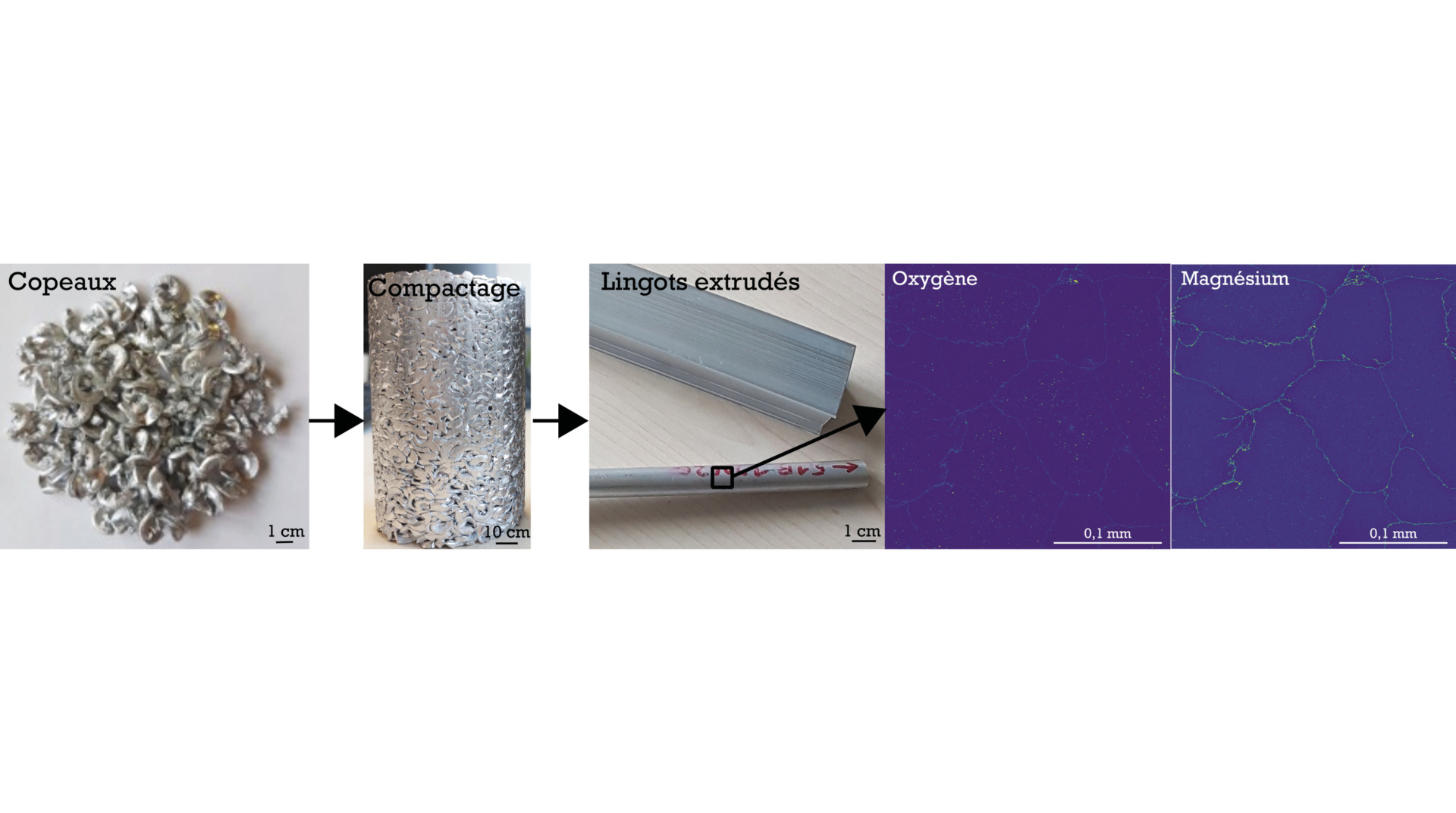

Recycling 2.0

Solid-state recycling of aluminum alloys, an innovative process for enhanced sustainability